Sodium vapor vs. LED-Tech – We have a winner!

Especially in commercial horticulture, but also in semi-professional existing grow rooms, the replacement of the classic 600W sodium vapour luminaire with our LED technology is often requested. In this blog post, we analyse how 600W sodium vapour luminaires can be cost-effectively replaced by our SANlight EVO-Series.

A few years ago, the challenge was to replace classic sodium vapour luminaires (NDL) with Led technology in an economically sensible way. The ambitious goal was to achieve similar light intensities and light distributions across the surface without breaking the customer’s budget. But with the market launch of SANlight EVO at the latest, the motto is maximisation, not substitution. For example, the lighting setups we recommend, see the blogpost PAR test and PPFD plot, provide on average 50% more light with significantly more homogeneous light distribution. The electrical power used is still 25% lower. Compared to the “old” technology, yields can be produced that were considered impossible just a few years ago. Yields of up to 0.9 kg per square metre are realistically achievable with our luminaires.

Nevertheless, there are customers who simply want to replace their sodium vapour luminaire 1 to 1. The pure substitution of sodium vapour luminaires is about replacing the sodium vapour luminaire as cost-effectively and simply as possible. In operation, the energy-saving potential should be fully exploited without sacrificing the quality and quantity of the harvest.

Substitution of sodium vapour luminaires, the basics

The basis of the substitution of the sodium vapour luminaire with our EVO-Series is to achieve the same output (PPFe). The table below shows which model of the EVO-Series can be used to replace corresponding NDLs.

| HPS lamp | PPFe | Output | LED-replacement | PPFe | Output | Remark |

| 400W | 560µmol/s | 425W | EVO4-XXX | 696µmol/s | 250W | 41% energy saving

24% more PPFe |

| 600W | 840µmol/s | 640W | EVO5-XXX | 870µmol/s | 320W | 50% energy saving

4% more PPFe |

Advantage of light control with the SANlight EVO-Series

The light generated by a sodium vapour lamp is emitted at a 360° angle. To direct these photons to the plants, a reflector must be used. This directs the light downwards. However, a reflector can only direct the light of the NDL to a limited extent. This results in large losses in open spaces, as a large part of the light is lost to unplanted areas. With the secondary optics used in our EVO-Series, these losses to unplanted areas can be significantly reduced because the light control is very precise.

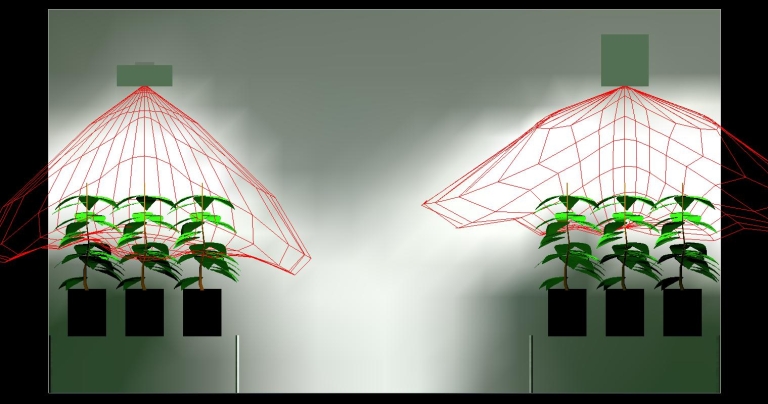

Comparison of radiation characteristics NDL vs. SANlight EVO-Series

1 to 1 replacement for 1m deep planting tables

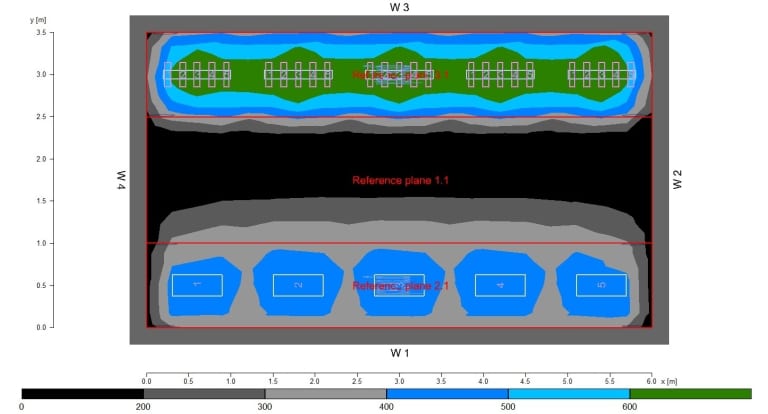

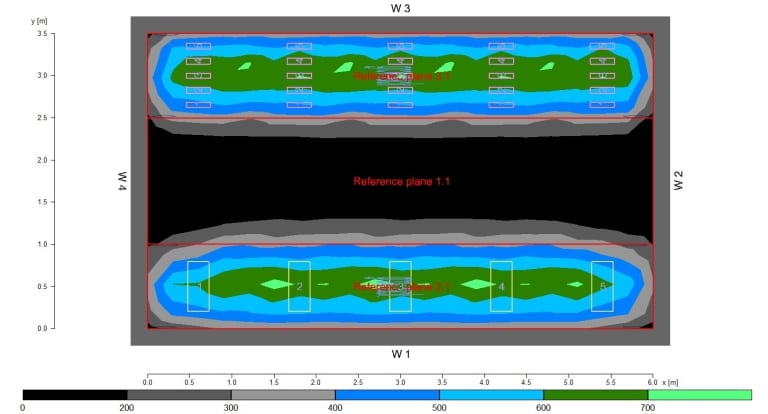

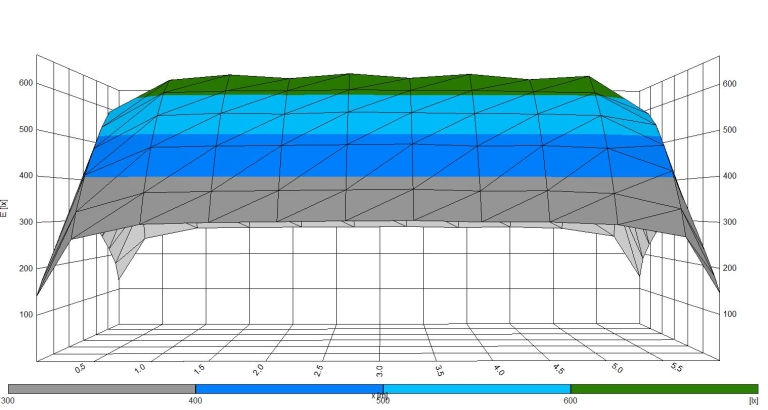

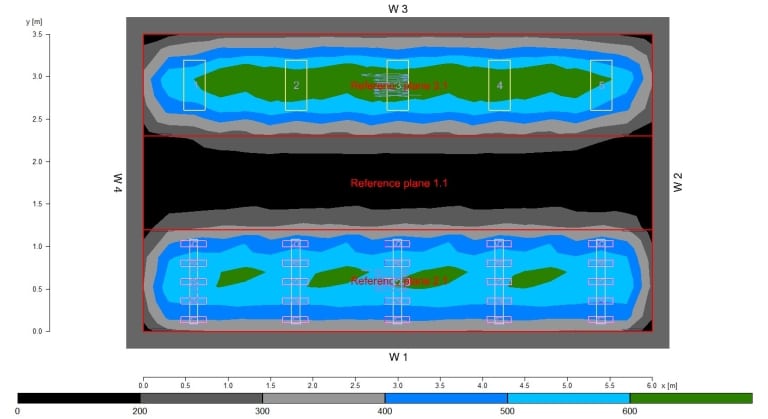

How does the light distribution of the luminaires behave when larger areas are illuminated with several luminaires? To answer this question, rooms with dimensions of 6×3.5x2m were simulated. In the rooms, two rows of tables were positioned against the walls with a depth of one metre and the length of the room. Five 600W HPS luminaires (Gavita Pro 600e) were used per planting table. The five HPS luminaires per planting table were arranged classically with a distance of 120cm to each other. On the second table, 5 EVO 5-100 luminaires were positioned in the same place.

As can be seen in the PPFDe plot (right), both illumination systems achieve an almost identical and very good homogeneity of the light distribution of over 70%. However, the 600W HPS variant only achieves an average illumination intensity of 400µmol/m²/s, whereas the EVO 5-100 variant achieves an intensity of 539µmol/m²/s. In this example, the set-up with EVO5-100 luminaires provides 35% more light to the planting area with almost the same homogeneity. While there is only 287µmol/m2/s in the peripheral areas of the planting area under the sodium vapour luminaire, the EVO5-100 Set Up achieves 395µmol/m2/s here. The energy saving is 50%.

2D PPFDe plot, NDL vs. SANlight EVO, longitudinal arrangement, table width 1m

| 600W HPS | EVO 5-100 | ||

| Average intensity | Em | 400 µmol/m²/s | 539 µmol/m²/s |

| Minimum intensity | Emin | 287 µmol/m²/s | 395 µmol/m²/s |

| Maximum intensity | Emax | 456 µmol/m²/s | 651 µmol/m²/s |

| Homogeneity | Emin/Em | 72% | 73% |

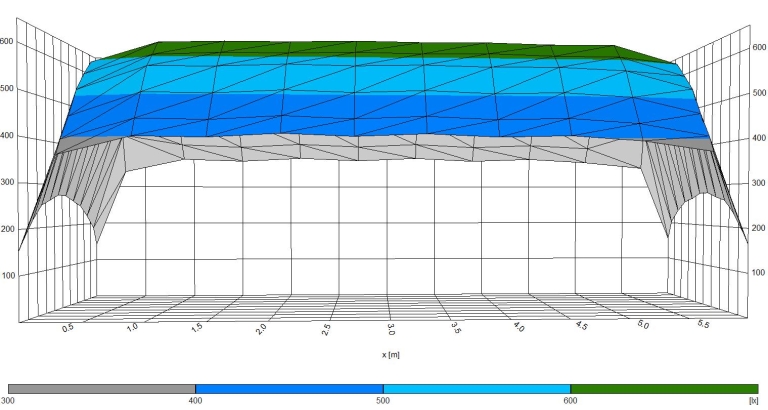

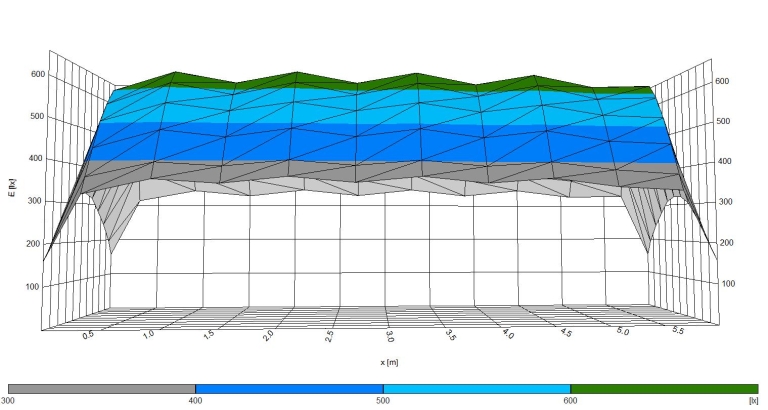

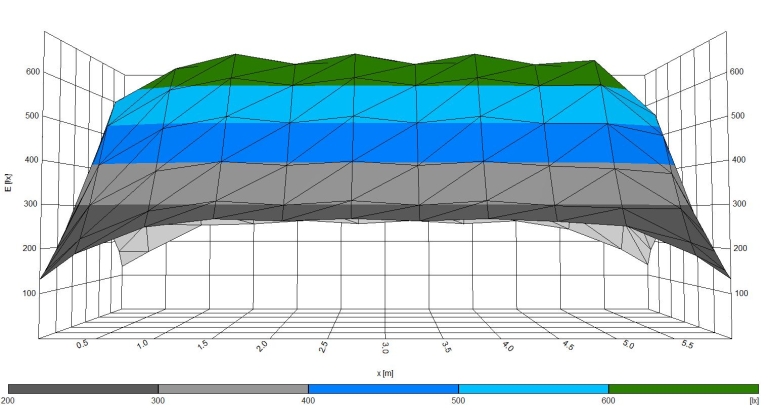

When looking at the three-dimensional PPFD plot over the length, it is noticeable that both versions distribute the light homogeneously over the length of the table. The EVO-Series has a slight advantage here. However, the 35% higher PPFD values achieved with the SANlight EVO-Series should be emphasised.

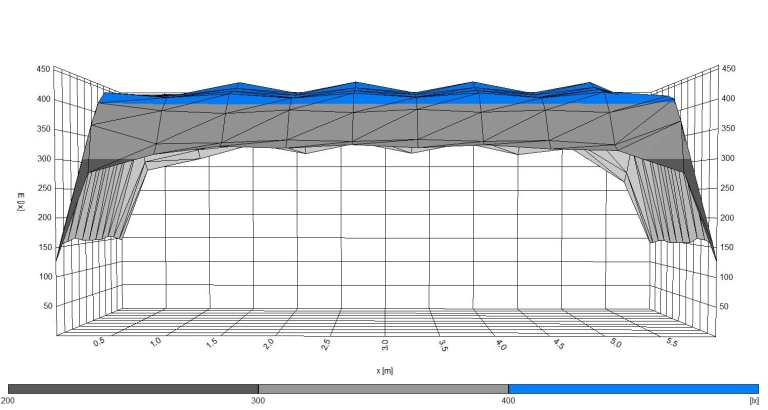

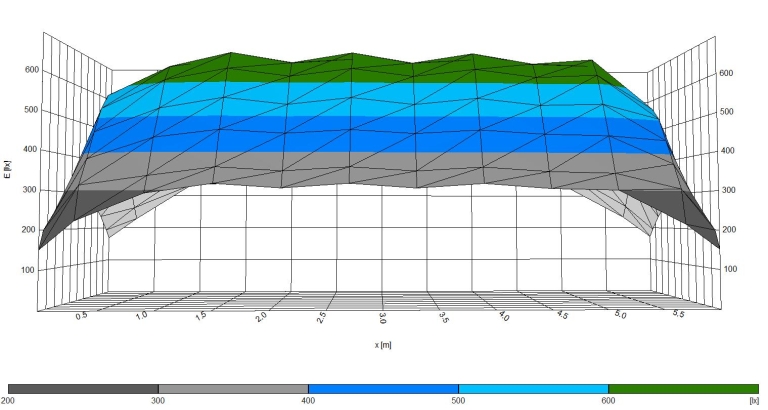

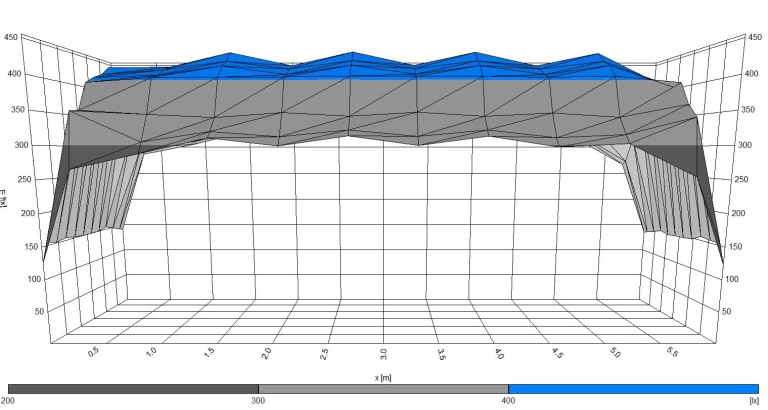

To complete the comparison, the luminaires (NDL and EVO 5-100) were rotated by 90° in another simulation. This is to check whether this has a positive effect on the light distribution. Both the sodium vapour luminaires and the SANlight EVO luminaire have an asymmetrical radiation characteristic, which has an influence on the light distribution. All other parameters have been retained so that the distance between the luminaire and the planting surface is still 60cm.

Compared to the previous simulation, the average illumination intensity for the HPS luminaire has increased by over 100µmol/m²/s, although the uniformity has reduced from >70% to just under 50%. While the minimum intensity of 262µmol/m²/s is slightly lower than before, the maximum intensity has increased to almost 697µmol/m²/s. This is an increase of over 240µmol/m²/s. This is an increase of over 240µmol/m²/s. The correct arrangement of the luminaire strongly influences the illumination intensity as well as the light distribution with the NDL, and can be attributed to the asymmetrical radiation characteristic.

With the EVO luminaire, rotation results in a marginal reduction of the Ø PPFDe 539µmol/m²/s to 528µmol/m²/s. The maximum PPFD has also increased slightly due to the different positioning of the EVO luminaires. However, the min. PPFDe values are also reduced at the same time. The homogeneity on the EVO luminaire side remains largely unaffected by the rotated arrangement. The effect of the orientation of the luminaires is low with the EVO-Series.

2D PPFDe plot, NDL vs. SANlight EVO, transverse arrangement, table width 1m

| 600W HPS | EVO 5-100 | ||

| Average intensity | Em | 517 µmol/m²/s | 528 µmol/m²/s |

| Minimum intensity | Emin | 262 µmol/m²/s | 359 µmol/m²/s |

| Maximum intensity | Emax | 697 µmol/m²/s | 658 µmol/m²/s |

| Uniformity | Emin/Em | 51% | 68% |

Looking at the three-dimensional PPFDe plots also shows no surprising result. Both systems distribute the light evenly over the length of the table in this arrangement. If both previous simulations are considered, it can be said that the sodium vapour luminaire in this example is clearly more sensitive to unfavourable positioning.

In this realistic scenario, we were able to prove that 600W sodium vapour luminaires can be replaced 1 to 1 by SANlight EVO5 Led luminaires. The following advantages result for the customer from this conversion:

- Energy savings of at least 50%

- More homogeneous illumination

- Up to 35% more light with 50% energy savings

- Less waste heat from the Led luminaire

- Better quality light spectrum of the Led luminaire

- Longer service life of the Led luminaire

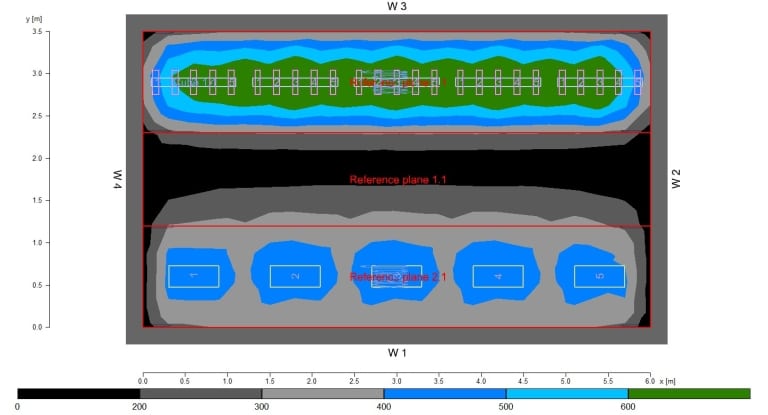

1 to 1 replacement for 1.2m deep planting tables

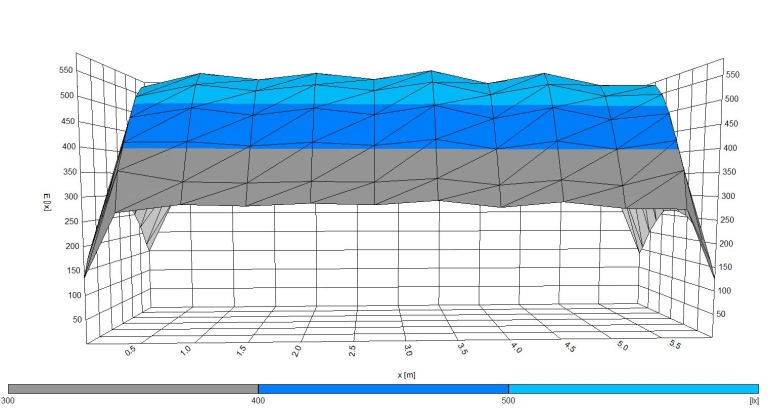

Again, the room was simulated with 6×3.5x2m. This time with two rows of tables of 1.2x6m each. Again, five 600W HPS luminaires and five EVO 5-100 were positioned above the planting area. The distance between the lower edge of the luminaires and the plants is again 60cm. All parameters except for the depth of the tables were kept.

In the PPPDe plot (right) it can be seen that the sodium vapour exposure system only insufficiently illuminates the surface. The average exposure intensity is 385µmol/m²/s for the area exposed with NDL. It is clearly visible that the EVO-Series provides much better light values. With an Ø PPFDe of 508µmol/m²/s, the EVO-Series offers clear advantages in this application example. With the maximum and minimum values, the EVO is ahead with 661µmol/m²/s and 322µmol/m²/s respectively. The homogeneity of the NDL version is slightly better at >70%.

2D PPFDe plot, NDL vs. SANlight EVO, longitudinal arrangement, table width 1.2m

| 600W HPS | EVO 5-100 | ||

| Average intensity | Em | 385 µmol/m²/s | 508 µmol/m²/s |

| Minimum intensity | Emin | 273 µmol/m²/s | 322 µmol/m²/s |

| Maximum intensity | Emax | 455 µmol/m²/s | 661 µmol/m²/s |

| Uniformity | Emin/Em | 71% | 63% |

In the 3D PPFDe plots, the good light distribution over the table length of both systems can be seen. In the case of the table exposed with sodium vapour lamps, it can be seen from the 3D PPFDe plot that there is too little light. The generative phase of short-day plants, such as cannabis, would only be feasible to a limited extent here.

Also for the table width of 120cm we turned the luminaires by 90° to get an impression of the change. Since it is a table with a depth of 120cm, the EVO 5-120 Led luminaire was chosen.

The PPFDe plots show a clear result. It can be seen that the correct arrangement of the sodium vapour luminaires is decisive for their usability. Compared to the longitudinal arrangement, the system with 90° rotated sodium vapour lamps is clearly more usable. The average PPFDe increases from 385µmol/m2/s to 478µmol/m2/s. At the same time, however, the PPFDe deteriorates. At the same time, however, the homogeneity deteriorates from 71% to 45%. On the EVO side, rotating the luminaires also has an effect on the Ø PPFDe. This drops from 508µmol/m2/s to 466µmol/m2/s due to the rotation. However, the homogeneity of the led set-up increases to 69%.

2D PPFDe plot, NDL vs. SANlight EVO, transverse arrangement, table width 1.2m

| 600W HPS | EVO 5-120 | ||

| Ø Intensity (PPFDe) | Em | 478 µmol/m²/s | 466 µmol/m²/s |

| Minimum intensity (PPFDe) | Emin | 213 µmol/m²/s | 322 µmol/m²/s |

| Maximum intensity (PPFDe) | Emax | 693 µmol/m²/s | 584 µmol/m²/s |

| Uniformity | Emin/Em | 45% | 69% |

The 3D PPFDe plots show us that the side with sodium vapour luminaires achieves a significantly higher PPFDe peak with this arrangement. The sodium vapour luminaire produces a band of high light intensities centrally along the length of the table. However, these values drop sharply, which would lead to very uneven growth. The 120cm deep planting table is only partially usable with 5 x 600W sodium vapour luminaires. The Led side delivers less high maximum values, but the light is distributed much more evenly over the surface. So the whole table would be usable here.

Conclusion

The previous comparison, which was carried out through 4 different simulations, produced the following results:

- 1-to-1 replacement of a 600W sodium luminaire with an EVO 5 series model is possible

- more than 50% energy saving by replacing 600W sodium luminaire with EVO 5

- better Ø PPFDe values by replacing 600W sodium vapour luminaires with SANlight EVO 5

- better homogeneity by replacing 600W sodium vapour luminaires with SANlight EVO 5

- Orientation of the sodium vapour luminaire (longitudinal or transverse to the planting table) has a strong influence on the light distribution and the Ø PPFDe

- correct orientation of the sodium vapour luminaire results in up to 25% more PPFDe

- correct orientation of the sodium vapour luminaire brings up to 26% better homogeneity

- Orientation of the EVO 5 luminaires (lengthwise or crosswise to the planting table) has little influence on the light distribution and the Ø PPFDe

- correct orientation of SANlight EVO 5 luminaires results in 9% more PPFDe

- correct orientation of the SANlight EVO luminaires brings up to 6% better homogeneity

- SANlight EVO luminaire provides more uniform illumination of the planted area

Cost calculation

Compared to the sodium vapour luminaire used here (Gavita E-Series Pro 600), the SANlight EVO series incurs approx. 35% higher initial costs. The initial costs for end users per luminaire are € 140* higher. With an average exposure time of 14h per day and an electricity price of € 0.2 per kWh*, the higher initial costs are amortised after approx. 160 days.

*Prices as of 25.02.2022. With changing prices the cost amortisation will vary.